June 2, 2015

FOR IMMEDIATE RELEASE

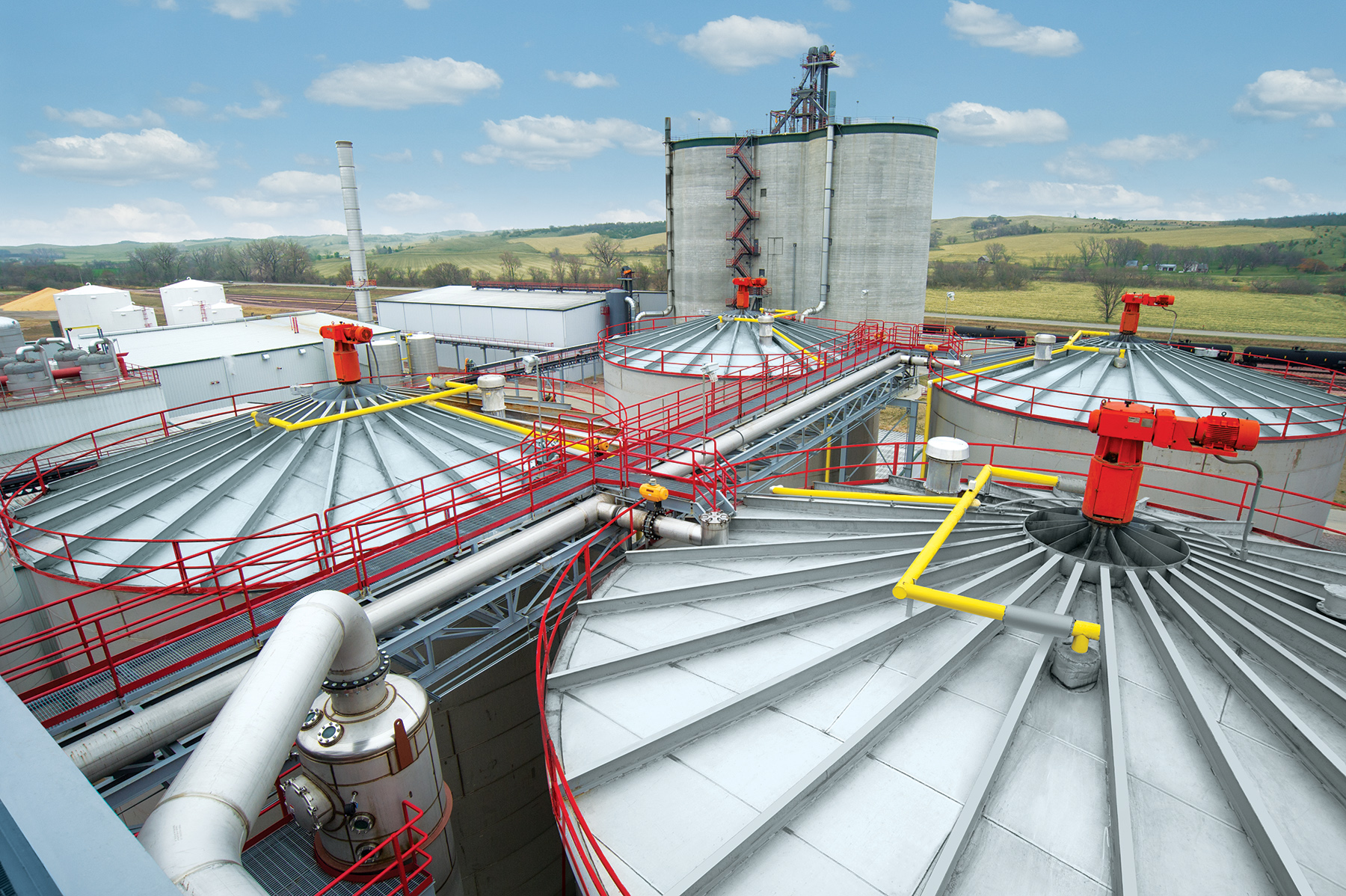

Solenis' fermentation aids allow fuel ethanol producers to improve fermentation efficiency and increase ethanol yields without the use of antibiotics.

Novel antibiotic-free fermentation aids effectively control undesirable microorganisms in the fermentation process while simultaneously promoting and aiding yeast propagation

WILMINGTON, Del. (USA) — Solenis, a leading global producer of specialty chemicals, has launched a novel family of antibiotic-free fermentation aids to help fuel ethanol producers improve efficiency and address regulatory and consumer concerns about antibiotics in the food chain.

The new products were introduced at the 2015 International Fuel Ethanol Workshop & Expo (FEW) in Minneapolis, Minn.

The Solenis' family of fermentation aids, which includes three patented and patent-pending products, significantly enhances the ability of yeast to compete with undesirable microorganisms in the critical initial stages of propagation and fermentation without the use of antibiotics-an increasingly important goal for fuel ethanol producers.

Most fuel ethanol operations are considered food producers. Distillers grains generated as a co-product of fuel ethanol production have become a primary ingredient in animal feed and therefore are a significant element in the food chain. Today's typical fermentation processes control undesirable microorganisms using antibiotics, which remain in the resulting distillers grains.

"As consumer demands and regulatory requirements continue to become more stringent, current antimicrobials, and specifically antibiotics, may be further subject to maximum contaminate limits", said Allen Ziegler, global biorefining marketing director. "As a result, our new fermentation aids give fuel ethanol producers more tools to address undesirable microorganisms without antibiotics, while helping them boost production and satisfy consumers at the same time."

Designed to promote beneficial yeast growth and efficiency in both high pH and standard pH fermentation processes, Solenis fermentation aids are based on advanced proprietary and targeted antimicrobial technology. While the products were initially developed for fuel ethanol production, they also have practical application in other commercial fermentation processes.

"We will continue to anticipate and proactively address our customers needs to optimize processes while staying ahead of evolving regulations", said John Panichella, president and CEO. "With close to 100 years of experience in process and water treatment chemistries, Solenis is committed to serving the fuel ethanol and biorefining industries with our well-respected and diverse product line, along with our application expertise and our investment in research and development."

The fermentation aids represent one of many solutions recently developed for fuel ethanol producers by Solenis, which was previously known as Ashland Water Technologies. Other process and water treatment innovations include FDA-approved corn oil extraction aids for both disk-stack and tricanter systems; a proprietary control system that allows for around-the-clock surveillance and control of process and water treatment programs; a low-corrosion microbiocide for cooling water systems; and novel scale inhibitors for evaporators.

For more information about the Solenis' family of fermentation aids, visit solenis.com/fermentation

About Solenis

Solenis is a leading global provider of water and hygiene solutions. The company’s product portfolio includes a broad array of water treatment chemistries, process aids, functional additives, cleaners, disinfectants, and state-of-the-art monitoring, control and delivery systems. These technologies are used by customers to improve operational efficiencies, enhance product quality, protect plant assets, minimize environmental impact, and create cleaner and safer environments. Headquartered in Wilmington, Delaware, the company has 70 manufacturing facilities strategically located around the globe and employs a team of over 16,500 professionals in 130 countries across six continents. Solenis is a 2025 Best Managed Company Gold Standard honoree.

For additional information about Solenis, please visit www.solenis.com or follow us on social media.