Over the last decade, the pulp and paper (P&P) industry has embraced two popular, emerging trends—sustainability and artificial intelligence (AI). To date, most corporate strategies tend to focus on these initiatives independently of one another. However, now is the time to put AI to work on the sustainability front!

Regarding sustainability, the P&P industry faces much scrutiny because of the resource-intensive nature of the industry. Most P&P mill managers have well-defined targets for sustainability. They commit to preserving natural resources while striving to have a positive influence on the environment and to avoid having a negative influence on social and economic issues. These sustainability goals include:

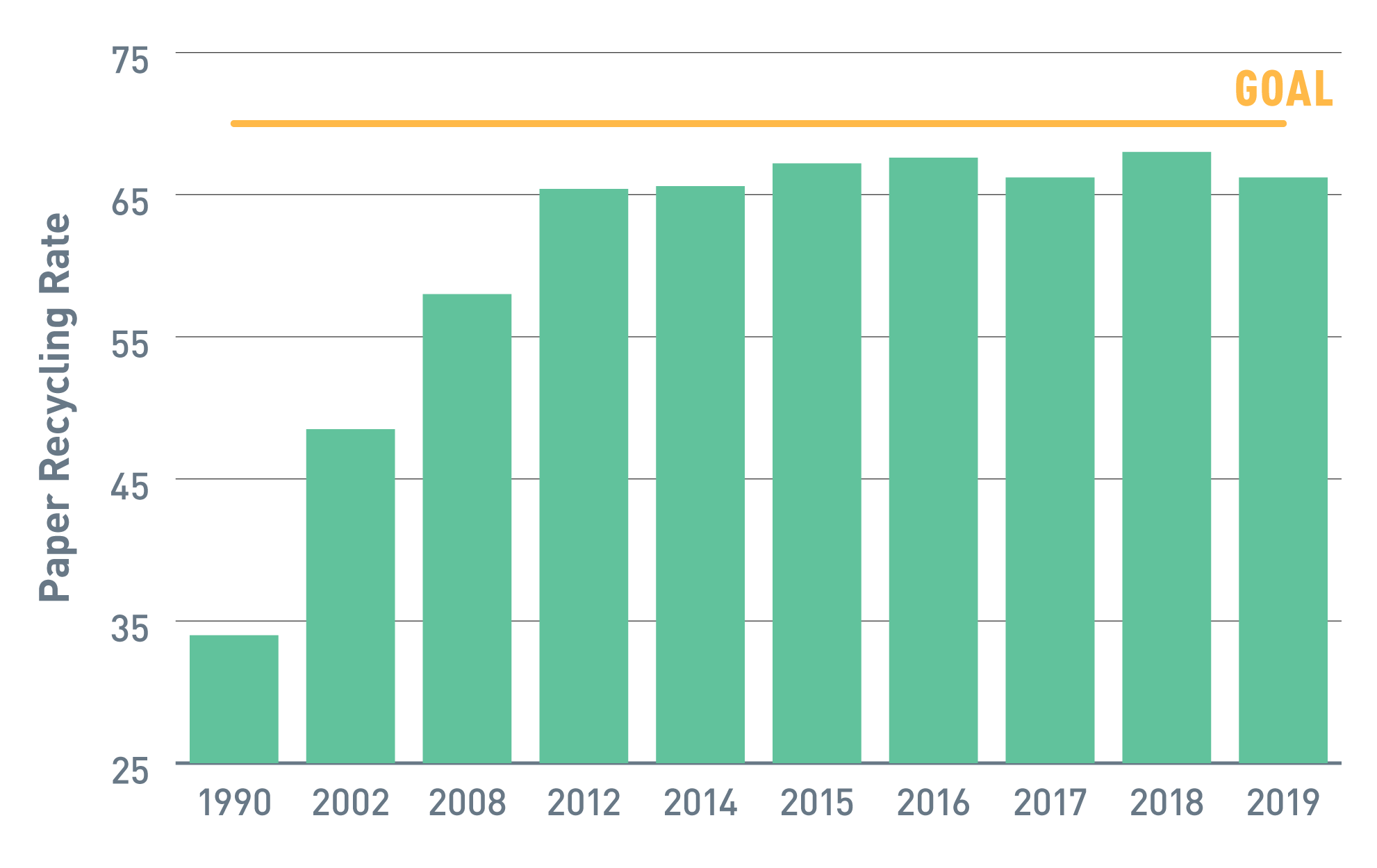

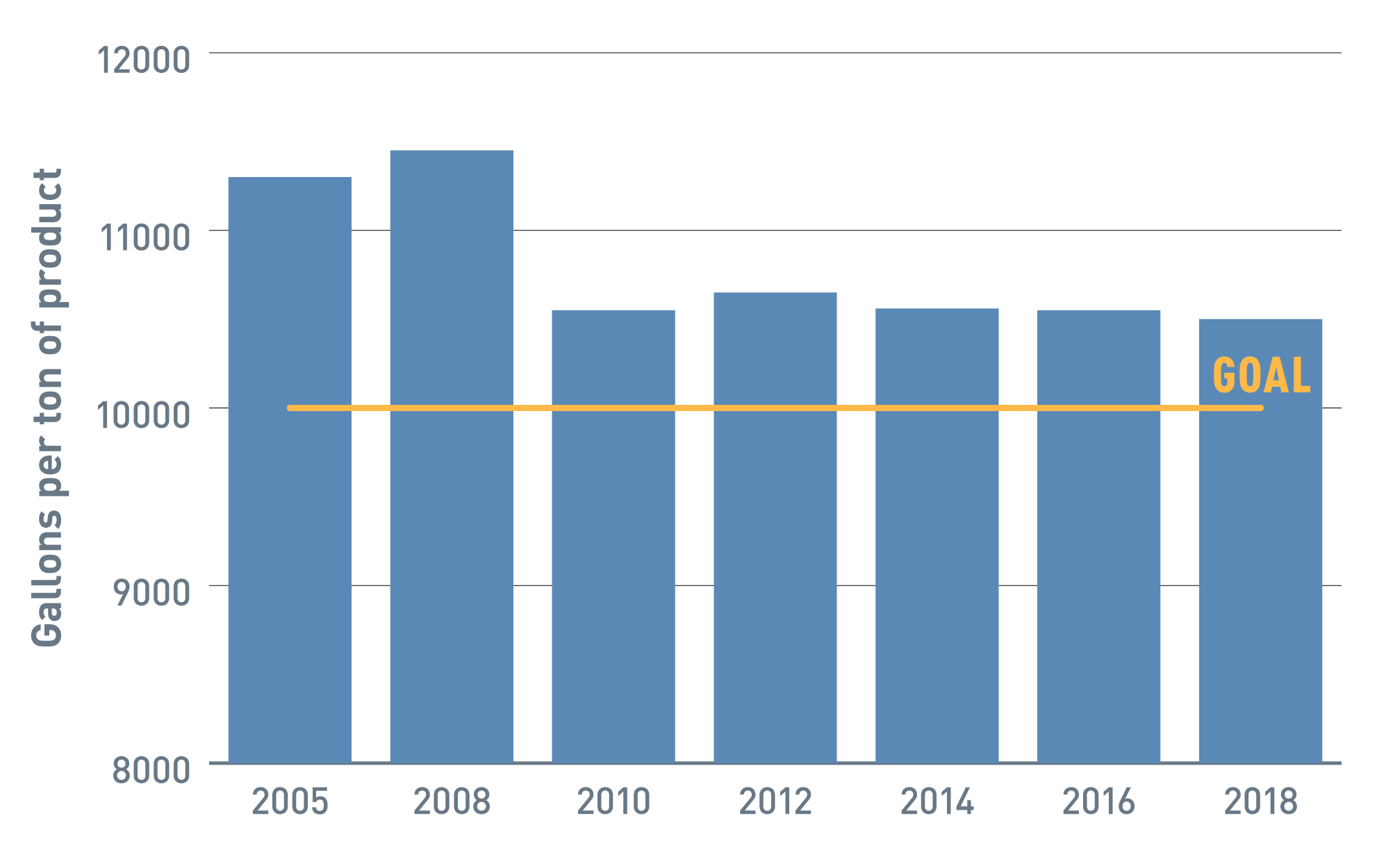

The American Forest & Paper Association (AF&PA), in their 2020 Sustainability Report, acknowledges the major achievements of the P&P industry. Nevertheless, several unmet goals, including paper recovery (for recycling) and water use, remain (Figure 1).

a.

b.

Figure 1. Annual underperformance of AF&PA members’ sustainability goals: (a) paper recovery for recycling and (b) water use. (Source: 2020 AF&PA Sustainability Report)

Sustainability goals can be achieved through smarter, sustainably-conscious manufacturing, but achieving them will likely require an in-depth analysis and an extensive plan of action. Additionally, once mill managers meet all their current sustainability targets, they will be pressured to establish more ambitious goals to accelerate additional changes. So how do you achieve additional sustainability goals after the “easy” targets have been hit?

The manufacturing process provides several opportunities to realize these sustainability goals. However, paper production—a rapid manufacturing environment with difficult-to-measure quality tests and limited real-time optimization opportunities—presents a unique challenge. One wrong move could upset the entire process.

Nowadays, P&P mill operators utilize their distributed control system (DCS) and their multitude of installed sensors to closely monitor and control their process. To optimize the process, mill operators and engineers must rapidly analyze the data and quickly adjust inputs. This is where AI can help. AI techniques, such as machine learning and predictive modeling, require vast amounts of historical data to begin grouping influencers together; detecting production anomalies; or constructing models for predictive, prescriptive, or root-cause analytics. These techniques are incredibly useful for sorting through the massive amounts of data collected at P&P mills. New AI products are available to monitor, track and analyze historical and real-time data. AI products also create process models and provide autonomous control.

AI-enabled Solutions for Sustainability

Fusing human and artificial intelligence enables P&P mills to tackle the toughest sustainability challenges. Specifically, AI-driven autonomous control presents mill operators with the opportunity to consistently achieve sustainability goals while optimizing production inputs. In the case of fiber utilization, allowing AI to make decisions about fiber dosage and furnish selection provides operators with several opportunities to reach sustainability goals:

- Auto-optimized fiber consumption: uses only the amount of fiber needed to meet the quality requirements (Goal – Forestry)

- Auto-adjusted furnish mix: selects the most economical and sustainable fiber blend and incorporates recycled or off-quality paper (Goal – Forestry, Waste)

This is accomplished by utilizing AI and machine learning to create a virtual sensor for the key quality parameters and subsequently incorporating an AI-driven feedback control loop to optimize the furnish. Because fiber quality and machine conditions can vary from minute to minute, machine learning is a key component of this process. Machine learning allows the AI system to make process adjustment decisions more rapidly and more frequently than operators could.

By extrapolating this example to additional applications within the papermaking process, AI decision making and autonomous control can help mill managers realize their remaining sustainability goals. Examples include:

- Auto-optimized chemistry dosing: improves sludge dewatering thus creating sludge that requires less energy to burn or less waste to be shipped to landfills (Goal – Energy, Emissions, Waste)

- Autonomous biocide dosing: prevents formation of volatile fatty acids (VFA) and requires less freshwater (Goal – Water)

Solenis’ Focus on Sustainability

At Solenis, our vision is to enable our customers’ success through innovative process and water treatment solutions. AI-driven solutions provide a transformational approach to managing resources and manufacturing processes more effectively. By combining chemistries and AI-driven technologies, Solenis is supporting our customers’ commitment to a more sustainable future. Through our OPTIX™ Applied Intelligence platform—a machine-learning, autonomous-control solution—customers are achieving operational savings and meeting sustainability goals.

Click here to read Solenis’ 2020 Sustainability Report.