Evidence of airborne transmission of the SARS-CoV-2 virus (Coronavirus) in enclosed environments has recently been published by scientists in the Clinical Infectious Diseases journal and the WHO has recognised that further studies into modes of transmission are required. Existing studies indicate that SARS-CoV-2 particles can remain infectious on various materials, as well as in aerosols in indoor environments, with the duration of infectivity depending on temperature and humidity.

Although COVID-19 has been thought to be primarily transmitted via large respiratory droplets, an increasing number of outbreak reports implicate the role of aerosols in the transmission of the virus. Aerosols consist of small droplets and droplet nuclei which remain in the air for longer than large droplets. The following guidance details methods to increase air quality and reduce the risk of transmission by air handling systems in food and beverage production facilities.

Most importantly, the creation of aerosols in a factory should be avoided where possible.

Air Handling - System Design and Maintenance

A well balanced and hygienically maintained air filtering system is recommended. Well-maintained HVAC systems, including air-conditioning units, are able to securely filter large droplets containing SARS-CoV-2.

System Design

- Air filters should be considered as part of the boundary between hygienic zones, e.g. medium hygiene on the unfiltered airside and high hygiene on the clean, filtered airside.

- H13-14 filter systems can retain SARS-CoV-2 containing aerosols < 5?m, and should be implemented in zones with higher exposure risks. These filters should be implemented in a 3-stage system, with an F7 stage, followed by an F9 and then finally an H13/H14 filter.

- Process air must not be drawn from dry material handling and packing areas, as these are usually potential areas of high dust loading.

- Air should flow from a higher to lower hygienic zone classification and from lower to higher dust loaded areas. Usually, an air pressure differential between the zones meets this requirement.

- The process plant should be operated under a slightly positive pressure (2-5 Pa) in order to prevent the ingress of unfiltered air.

- To meet different hygienic requirements (zone classification), random airflow between floors via stairways, lifts etc. must be prevented by installation of airlock systems.

System Maintenance

- Regular maintenance is critical. A cleaning and maintenance schedule should be implemented and audited against to ensure optimal operation of the air management and filtration system.

- Air filter elements should be changed at regular intervals or at the latest, if the permissible final pressure drop has been reached and before technical and/or hygiene deficiencies are observed.

- When changing the air filters, avoid any contamination of the environment, downstream air-conditioning units, and the rooms to which air is supplied. Make sure, in particular, that the new filters to be installed are not contaminated by dust.

- Personnel changing filters should wear suitable protective equipment.

- Replacement filters should be available prior to their requirement.

- A detailed record of air filter auditing and service work should be maintained.

The Aurora range* from Diversey Food and Beverage offers continuous disinfection of air during production to provide additional support to your existing factory air management processes. Available as stand-alone enclosed units with their own fan or to install into existing air ducts. Find out more.

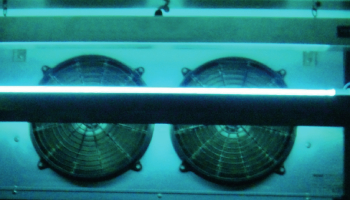

Air Handling - Evaporator and Chiller Units

Evaporator units and chiller units are normally cleaned on a periodical schedule. As these units act as ?localised air handling? they have the potential to spread any virus particles present in the local environment. The cleaning protocol and frequency should be updated and clearly identified in the site cleaning schedule. Diversey recommends:

- Deep cleaning of evaporator units to be carried out as a minimum every two weeks. Clean using Delladet* (EN 14476 tested) at 1.5 - 2.5% with a 5 to 10 minute contact time to provide effective performance against Coronavirus.

- Follow the deep clean with a treatment of neat Securegel* applied by spraying onto evaporator surfaces.

- Increase the frequency of Securegel* treatment to once or twice a week.

- Where contractors are responsible for the cleaning ensure the protocol and chemical regime is updated and aligned with your Coronavirus protocols.

- Carry out required preventative maintenance on evaporators and condensate pipework.

Air Handling - Wet Cleaning Considerations

Any wet cleaning that is necessary during production should be controlled wet cleaning either as a manual clean or with low pressure. Cleaning with the appropriate low-pressure nozzles should be managed and enforced consistently.

*Please contact your Diversey representative to confirm local product range and availability products mentioned.